High-grade Digitizing for Embroidery: Expert Craftsmanship

High-grade Digitizing for Embroidery: Expert Craftsmanship

Blog Article

Understanding the Needlework Digitizing Refine: Your Ultimate Overview

Needlework digitizing is a careful craft that needs precision and competence to equate elaborate layouts into electronic styles for machine needlework. As artisans begin on this trip to grasp the embroidery digitizing procedure, a comprehensive understanding of the fundamentals sets the foundation for quality.

Comprehending Embroidery Digitizing Basics

Needlework digitizing basics form the foundation upon which intricate layouts are converted right into machine-readable layouts for specific sewing. This first action in the embroidery digitizing process is crucial for guaranteeing that the last embroidered item is a loyal depiction of the original style. Recognizing embroidery digitizing basics involves comprehending essential principles such as stitch types, sew instructions, thickness, padding, and draw compensation.

Stitch types play a crucial duty in determining the visual and textural outcome of the embroidered style. By selecting the proper stitch kind, whether it be satin, fill, or running stitch, digitizers can attain the wanted result and enhance the overall high quality of the embroidery. Additionally, stitch direction influences the circulation and dimension of the design, while thickness determines the spacing and coverage of the stitches.

Additionally, padding stitching provides security to the layout by safeguarding the textile and avoiding distortion during the embroidery process. Pull payment is an additional important consideration to counteract the natural tendency of fabric to agreement when stitched. Grasping these needlework digitizing basics is fundamental for creating professional-quality stitched products.

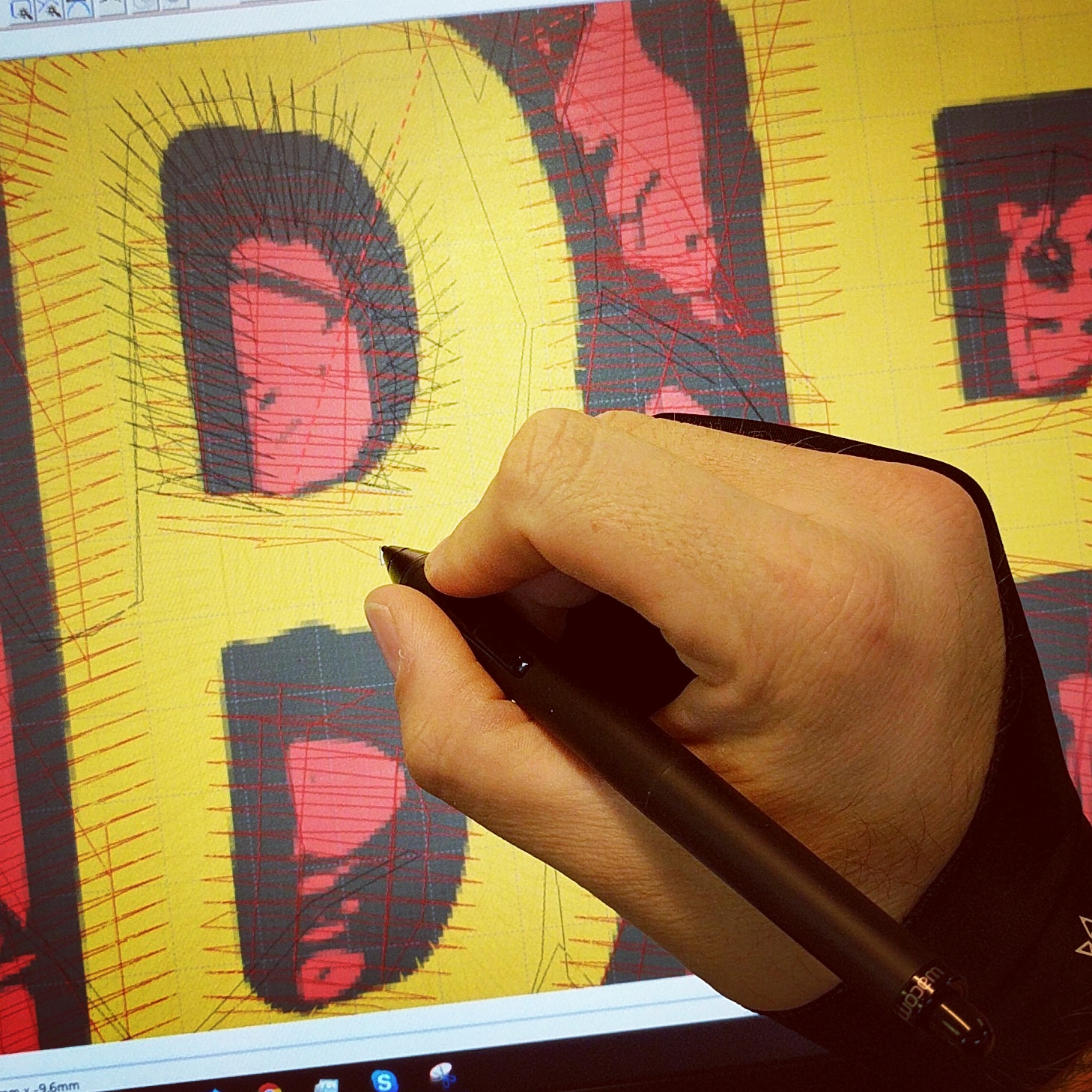

Choosing the Right Digitizing Software

Selecting the suitable digitizing software is an important choice that dramatically impacts the efficiency and quality of the embroidery digitizing procedure. Digitizing for Embroidery. When choosing the right digitizing software application, it is important to think about variables such as the intricacy of styles you prepare to produce, the user-friendliness of the software program, the level of client support used, and the compatibility with your embroidery equipment

There are various digitizing software options offered in the marketplace, ranging from basic programs for newbies to advanced software application for professional digitizers. Some popular selections include Wilcom EmbroideryStudio, Hatch Embroidery Software Program, and PulseID. These software use a variety of tools and features to help you produce detailed layouts with ease.

Prior to making a decision, it is a good idea to check out the various software program options through totally free trials or trials to figure out which one ideal fits your needs. Additionally, checking out evaluations and seeking recommendations my response from seasoned digitizers can supply useful understandings right into the toughness and weaknesses of each software (Digitizing for Embroidery). By very carefully evaluating your requirements and comparing the functions of different digitizing software, you can make an enlightened selection that boosts your embroidery digitizing process

Digitizing Devices and Techniques

Optimizing Style Setup for Embroidery

Mastering the complexities of layout settings is this essential in achieving optimum cause the embroidery digitizing process, structure upon the structure laid by understanding digitizing devices and strategies. When optimizing design setups for needlework, it is vital to take into consideration aspects such as stitch kind, thickness, rug, draw payment, and registration. Stitch kind option impacts the overall feel and look of the layout, with options like satin, fill, and running stitches supplying different appearances and results. Density describes the spacing and density of stitches, influencing the design's protection and longevity. Appropriate underlay stitching provides security and stops material distortion, especially for complicated styles or on stretchy products. Pull compensation adjusts for material stretch throughout sewing, ensuring accurate style duplication. Enrollment settings straighten various elements of the layout accurately, maintaining general design stability. By fine-tuning these style settings, embroiderers can boost the high quality and accuracy of their embroidered creations.

Troubleshooting Common Digitizing Issues

When encountering common digitizing issues during the needlework process, it is crucial to comprehend the origin and implement reliable options promptly. One typical trouble is stitch thickness concerns, where stitches may be too thick, triggering the fabric to pucker, or too thin, resulting in voids in the design. Readjusting the stitch thickness setups in the digitizing software application can assist solve this concern.

An additional frequent difficulty is string breaks during the needlework procedure. This can take place as a result look at here of different reasons such as inaccurate tension settings, dull needles, or making use of low-quality string. Ensuring proper maintenance of the embroidery machine, consisting of regular needle adjustments and stress changes, can minimize the event of thread breaks.

Furthermore, design registration errors can cause misaligned aspects within the needlework design. Examining the layout positioning in the digitizing software application and making needed adjustments prior to sewing can help in preventing this issue. By addressing these usual digitizing problems promptly and effectively, you can guarantee a smoother needlework procedure and high-grade finished items.

Conclusion

In conclusion, grasping the needlework digitizing procedure requires a strong understanding of the essentials, the best selection of software, and expertise of devices and strategies. Enhancing style settings and troubleshooting typical digitizing problems are crucial action in guaranteeing high-quality needlework outcomes. By adhering to these steps vigilantly, one can attain accuracy and effectiveness in the digitizing procedure.

Report this page